Robotics in Industry: Automation’s Impact on Jobs and Efficiency

Robotics in industry has ushered in a new era of automation, revolutionizing manufacturing processes, enhancing operational efficiency, and reshaping the workforce landscape. From assembly lines to warehouses, robots are increasingly deployed to perform repetitive tasks with precision, speed, and consistency, thereby reducing labor costs, improving product quality, and enabling businesses to remain competitive in a globalized economy.

The Rise of Robotics in Industry: Transforming Manufacturing and Beyond

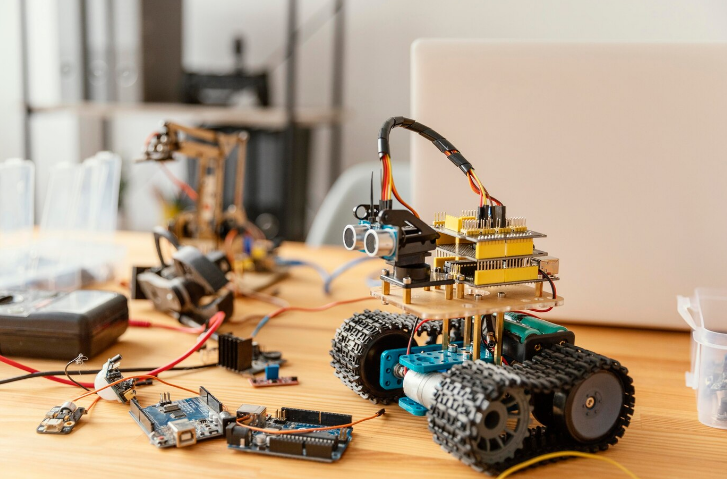

The integration of robotics into industrial operations marks a significant shift towards automation, driven by advancements in robotic technologies, artificial intelligence (AI), and machine learning. Industrial robots, equipped with sensors, actuators, and sophisticated control systems, are capable of performing a wide range of tasks—from welding and painting to packaging and quality inspection—previously handled by human workers.

Automation in manufacturing has enabled businesses to achieve higher levels of productivity and efficiency. Robots can operate continuously without fatigue, maintain consistent output levels, and perform tasks with greater precision and repeatability than human workers. This reliability translates into improved product quality, reduced error rates, and faster production cycles, allowing manufacturers to meet customer demands more efficiently and effectively.

Impact on Jobs and Workforce Dynamics

The widespread adoption of robotics in industry has sparked discussions about its impact on jobs and workforce dynamics. While robots have displaced some traditional manufacturing jobs that involve repetitive, manual tasks, they have also created new opportunities in robotics engineering, programming, maintenance, and supervision. These roles require specialized skills in robotics programming, troubleshooting, and system integration, reflecting a shift towards a more technology-driven workforce.

Moreover, robots and humans increasingly collaborate in a concept known as “cobots” or collaborative robots. Unlike traditional industrial robots confined to safety cages, cobots are designed to work alongside human workers in shared workspaces. Cobots are equipped with sensors and advanced safety features that enable them to detect and respond to human presence, facilitating safer and more efficient collaboration on assembly lines and in manufacturing environments.

The adoption of robotics and automation extends beyond manufacturing to sectors such as logistics, healthcare, and agriculture, where robots are deployed to streamline processes, enhance productivity, and mitigate labor shortages. In logistics and warehousing, robots powered by AI and computer vision technologies automate inventory management, order fulfillment, and logistics operations, reducing cycle times and optimizing warehouse space utilization.

In healthcare, robots assist surgeons in performing minimally invasive surgeries with precision and accuracy, improving patient outcomes and reducing recovery times. Autonomous robots are also employed in disinfection tasks, patient care assistance, and medication delivery in hospitals and healthcare facilities, augmenting healthcare professionals’ capabilities and improving operational efficiency.

Challenges and Considerations

Despite the benefits of robotics and automation, their adoption presents challenges related to cost, complexity, and societal implications. Implementing robotics systems requires significant capital investment in equipment, infrastructure, and training. Small and medium-sized enterprises (SMEs) may face barriers to adopting robotics due to high upfront costs and the need for specialized expertise in system integration and maintenance.

Furthermore, ensuring the safety and reliability of robotics systems is crucial to minimizing risks to human workers and optimizing operational performance. Robust safety protocols, risk assessments, and compliance with industry standards are essential to preventing accidents and ensuring regulatory compliance in industrial environments.

From a societal perspective, the increasing automation of jobs raises concerns about job displacement and economic inequality. While robotics and automation create new job opportunities in high-skilled sectors, such as robotics engineering and data analytics, they may contribute to job losses in low-skilled, routine tasks. Addressing these challenges requires proactive measures, including reskilling and upskilling initiatives, workforce development programs, and policies that promote inclusive growth and economic resilience.

Future Directions and Innovations

Looking ahead, the future of robotics in industry holds promise for continued innovation and advancements in autonomous systems, AI, and human-robot collaboration. Robotics technologies are evolving to become more intelligent, adaptive, and capable of performing complex tasks with human-like dexterity and decision-making capabilities.

Advancements in AI and machine learning are enabling robots to learn from experience, adapt to changing environments, and make autonomous decisions in real-time. This cognitive ability enhances the flexibility and versatility of robotics systems, enabling them to perform a broader range of tasks across diverse industries, from advanced manufacturing to healthcare and beyond.

Moreover, the convergence of robotics with other transformative technologies, such as 5G connectivity, edge computing, and IoT, is driving the development of interconnected and autonomous robotic systems. These integrated systems enable real-time data processing, enhanced communication, and coordination among robotic devices, facilitating collaborative workflows and optimizing operational efficiency in dynamic and interconnected environments.

In conclusion, robotics in industry represents a paradigm shift towards automation, efficiency, and innovation in manufacturing and beyond. While robotics technologies offer significant opportunities to enhance productivity, improve product quality, and create new job roles, addressing challenges related to cost, safety, and workforce implications is essential to realizing the full potential of robotics in driving sustainable growth and competitiveness in the global economy. Robotics’ transformative impact on industry underscores its role as a catalyst for innovation and a key driver of future advancements in automation and technology.